Installation Guide

Follow these instructions carefully to ensure proper installation of your crucible:

- Bottom stand made of the same material as the crucible ensures uniform heating and expansion, reducing thermal stresses.

- The stand should have the same diameter or slightly greater than the bottom of the crucible to provide adequate support.

- The height of the stand should align with the burner centerline for optimal heat transfer and melting efficiency.

- The crucible and stand should be centrally installed.

- Position the burner so the flame is tangential to the stand and crucible centerline.

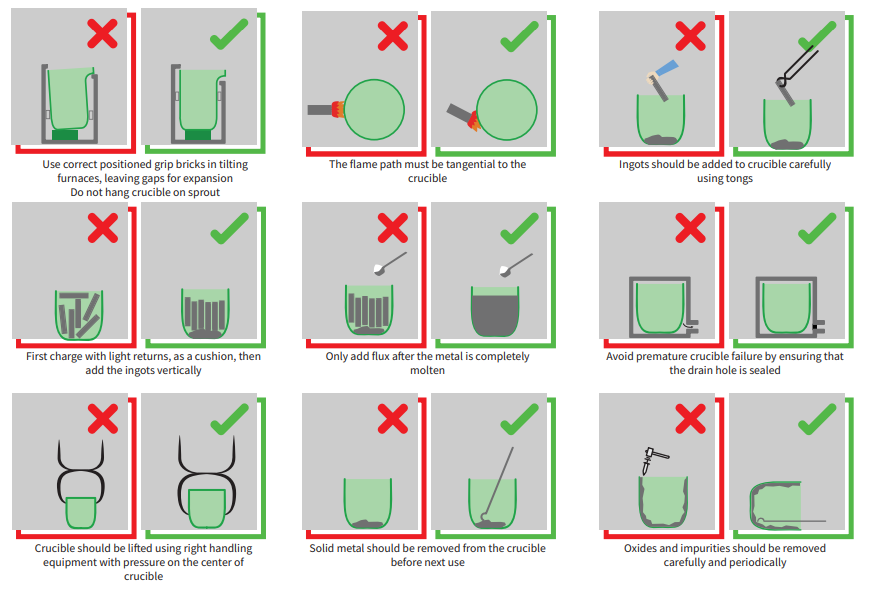

Tilting Furnace

- Place the stand on the metal base of the furnace, ensuring it is firm, central, and level.

- Spread cement evenly over the stand, excluding the spigot.

- Place the crucible centrally on the stand.

- Cement the key/grip bricks onto their support bricks, leaving a 6-10 mm gap between the crucible and key bricks.

- Insert cardboard or carbonaceous material in the gap and ensure key bricks are 75 mm below the crucible top edge.

- Leave a gap of 40 mm below the spout to avoid the crucible hanging on the spout.

Bale Out Furnace

- The top cover bricks should be set to leave a gap of 8 mm around the crucible to allow for expansion of the crucible and the furnace lining. Failure of the same can lead to cracking at the top of the crucible.

- A layer of insulating material, such as ceramic fibre, should be placed over the top of the lining and the top edge of the crucible in order to insulate the metal top plate. It should not be pushed down between the cover bricks and the crucibles.

- If the steel top ring is fitted, ensure that there is a gap of 12 mm between it and the inside of the crucible to allow for expansion. Too small a gap can lead to cracking at the top of the crucible.

Lift Out Furnaces

- To prevent the crucible from sticking to the stand, a thin layer of coke or other carbonaceous material should be sprinkled on top of the stand.

- The crucible should be placed centrally on the stand.

- Rocking and levering should not be done to free the crucible if it has stuck to the stand. It can cause fractures in the lower wall of the crucible.

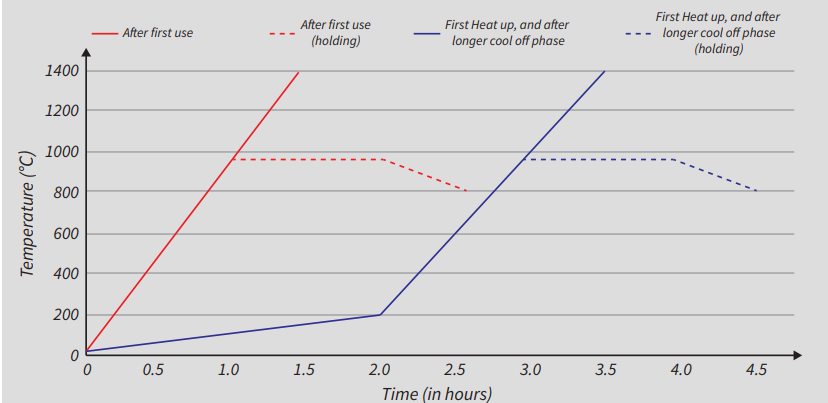

Preheating Guide

Heating recommendations for our Silicon Carbide Crucibles:

Instructions for Melting (First Installation)

The crucible should be slowly heated up to a temperature of 200°C over a period of two hours to remove any moisture that may be present.

The crucible should be then heated up to 600°C using low power.

The desired working temperature can then be reached at full power.

Instructions for Using Crucibles After a Long Gap

The crucible should be slowly heated up to a temperature of 200°C over a period of 2 hours to remove any moisture that may be present (Only after a long gap of use).

Once this temperature is reached, the heating procedure should be followed as per normal use.

Instructions for Holding (First Installation)

The crucible should be slowly heated up to a temperature of 200°C over a period of 2 hours to remove any moisture that may be present.

The temperature should be held at 950°C for approximately 1 hour to ensures melting of glaze along with anti-oxidation coating. This is necessary to achieve maximise crucible life.

This procedure always be done before reusing the crucible after a long time, and should be repeated at certain intervals.

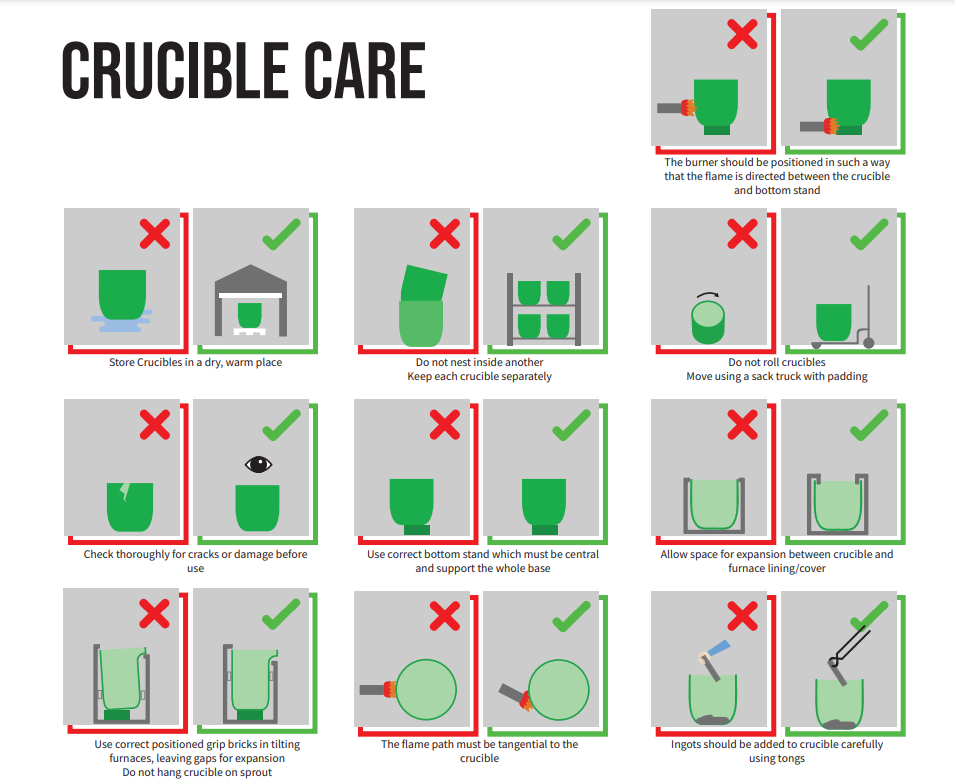

Crucible Care